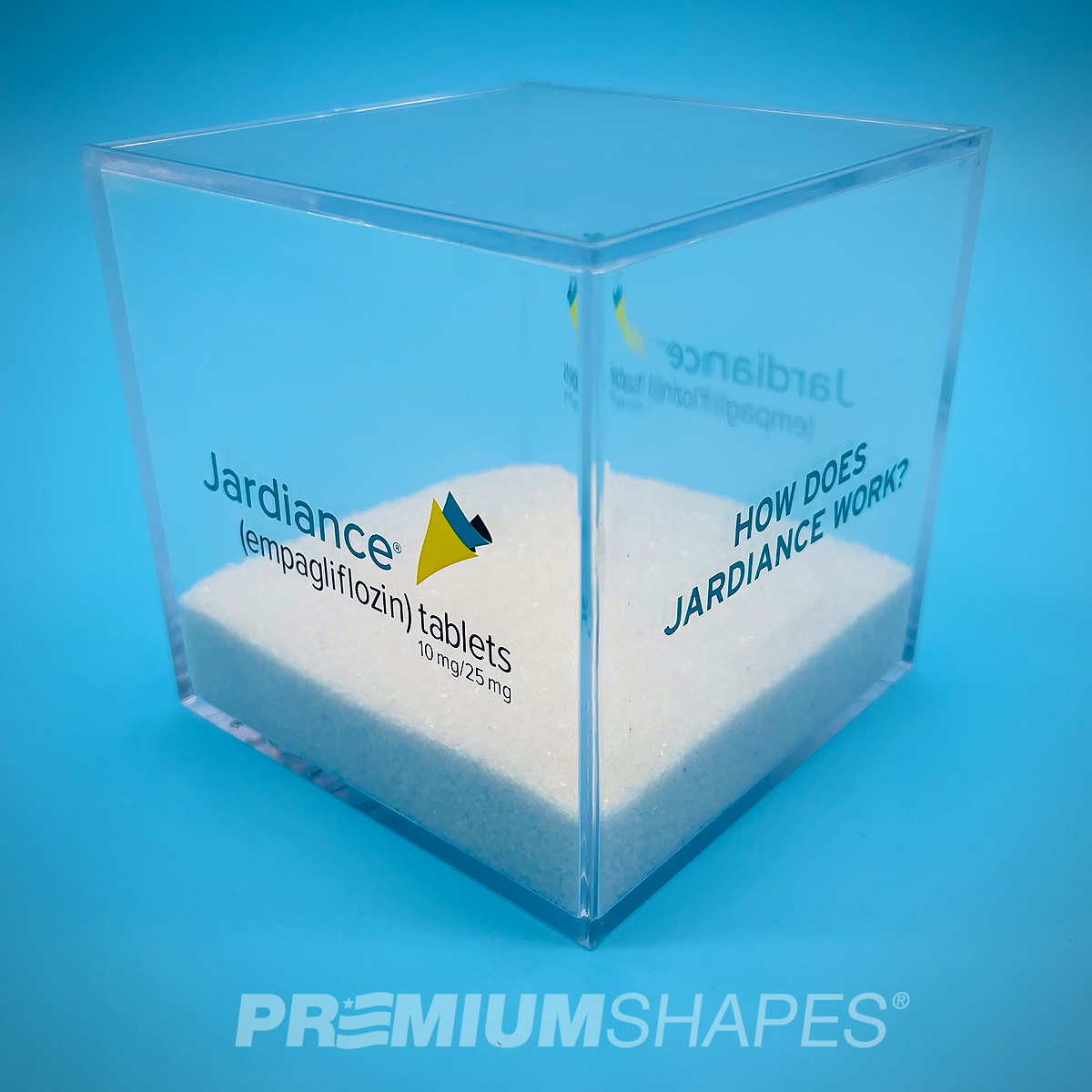

Project Description

This started out as a cool educational concept that took many turns. First quoted out domestically because of the tight deadline. There was no time for domestic tooling which means this was going to be made out of acrylic and have four color process printing on each side.

While we were making some domestic samples with direct printing on acrylic and versions with a 2 color silkscreening, we were also quoting at our overseas facility.

Due to the amount of labor and printing the overseas facility actually was a faster bet. Without a PO our facility took the gamble and started the tooling. Once the tooling was finished (in under two weeks) we made a few samples and rushed them to the client with unapproved artwork.

The samples were a hit and the next step was to decide on the grain of the sand. It needed to resemble sugar so we went thought a few samples of real white sand and manufactured sand. They chose the natural white sand. The final samples came in and everything was a go. The deadline was a little tighter and we now were producing the cubes 7 days a week with double shifts. At this point it was obvious this order would not of happened if we had not gambled on the tooling.

With custom jobs like this one there are always hidden things that come up and need immediate attention and immediate solutions. For this job it was the dust that came with the tons of natural sand. We implemented several cleaning stations and drying stations that rinsed, cleaned and dried the tons of sand to make the cubes crystal clear.

Once in final production we even delivered a few days early. Another reason to use the Sunscope family of manufacturing. Nowhere else can you find product engineers at your fingertips, domestic and overseas manufacturing, in-house patent council and hundreds of thousands of sq. ft. factory space.